In this section you will find inspirational examples of installations, applications of:

- Air operated diaphragm pumps (AODD)

- Centrifugal pumps

- SKID solutions

- Tapflo Solutions™ - Engineered to order (ETO)

- Mobile pumping solutions

Tapflo offers standard as well as tailored solutions for various industries and applications like Food & Beverage (F&B), transfer of chemicals, mechanical industries, surface treatment, water treatment, diaries just to name a few.

Chemically resistant diaphragm pump with extra suction lift

Pulsations in your process? - not with us!

AODD – perfect fit pumps for the packaging industry

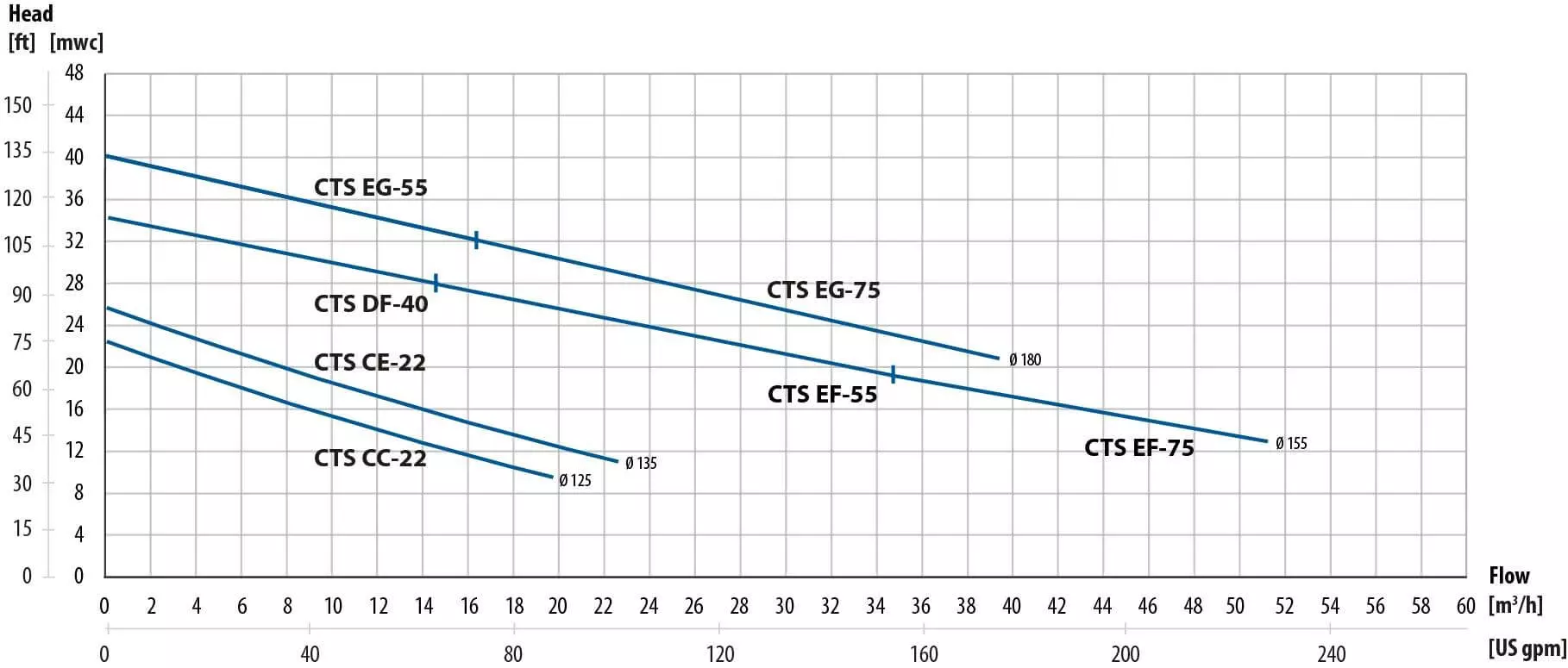

Technical data

| Model | CTS I | CTS H |

| Casing | Glass blast AISI 316L stainless steel | Electro polished Ra <0.8 μm AISI 316L stainless steel |

| Impeller | Glass blast AISI 316L stainless steel, open (standard) or optional semi-open type | Electro polished Ra <0.8 μm AISI 316L stainless steel, open (standard) or optional semi-open type |

| Mechanical seal | Single ceramic/graphite (standard), SiC/SiC or SiC/graphite, optional with oil lube | |

| O-rings | EPDM (standard), FKM, FEP/silicone or NBR | EPDM FDA requirements compliant (standard), FEP/silicone FDA requirements compliant or FKM FDA requirements compliant |

| Motor* | IEC standard, 3-phase, 2-pole, IP55 | |

| Pressure rating | PN 2,5 bar (CTS C) at 20˚C; PN 4 bar (CTS D,E) at 20˚C | |

| Temperature | max 90°C | |

| Viscosity | max ~200 cSt | |

| Particles | max diameter is Ø 6 mm (with standard open impeller), bigger if soft particles | |

The self-priming feature allows to use the pump in applications where standard CT pumps do not prove useful.

CTS is an open impeller self-priming centrifugal pump, manufactured from AISI 316L stainless steel.

CTS H with excellent electro polished surfaces, FDA approved seals, high finish and mechanical strength, meet the demands from food and sanitary applications.

CTS I with AISI 316L chemical resistance and mechanical strength is a reliable choice for industrial applications.

The self-priming feature allows to use the pump in applications where standard CT pumps do not prove useful. The CTS pump is capable of creating up to 4,5 m of suction lift.

Features & Benefits

- Wide range of optional executions: lubricated seal for safety, foot valve for quicker starting after stoppage of the pump, appropriate for hygienic applications (CTS H series).

- No need for additional pumps or equipment for self-priming.

- Ideal for highly aerated liquids.

- Easy installation and maintenance. Only the suction pipe has to be immersed and the pump can be located at a convenient spot. Disassembly of the pump can be done without interfering into the piping.

- Replace only one part on your CT pump to achieve the self-priming ability.

Typical APPLICATIONS

- Food & beverage (CTS-H series)

- Chemical & pharma (CTS-I & CTS-H series)

- Mechanical industry (CTS-I series)