In this section you will find inspirational examples of installations, applications of:

- Air operated diaphragm pumps (AODD)

- Centrifugal pumps

- SKID solutions

- Tapflo Solutions™ - Engineered to order (ETO)

- Mobile pumping solutions

Tapflo offers standard as well as tailored solutions for various industries and applications like Food & Beverage (F&B), transfer of chemicals, mechanical industries, surface treatment, water treatment, diaries just to name a few.

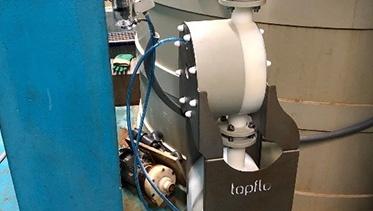

Chemically resistant diaphragm pump with extra suction lift

Pulsations in your process? - not with us!

AODD – perfect fit pumps for the packaging industry

Materials, data and limits

| Casing | Stainless steel AISI 316L, wetted parts: electropolished Ra<0.8 |

| Impeller | Stainless steel AISI 316L electropolished Ra<0.8 |

| Mechanical seal | Single, SiC/carbon (std) or SiC/SiC, FDA approved Double, SiC/carbon (std) or SiC/SiC, FDA approved |

| O-rings | EPDM, FKM, NBR (all FDA approved) |

| Motor | IP55; IEC frame B35; PTC thermistor; IE3; 3-phase |

| Pressure rating @ 20OC | PN10 – CTX 40-165, CTX 50-145, CTX 50-200, CTX 65-175 PN16 – CTX 65-230, CTX 65-240, CTX 80-205, CTX 80-212, CTX 80-260, CTX 100-230 |

| Liquid temp. | -10 °C ... +120 °C (140 °C for short periods during SiP) |

| Ambient temp. | -20 °C ... +40 °C |

| Viscosity | max ~150 cSt |

Built-on frequency inverter

This is easiest and most flexible way of changing pump working parameters.

In addition, the pump and motor are protected from overloading and a soft-start function is included.

Hygienic shroud

The hygienic motor shroud in AISI 304L protects the motor against flooding, deposition of dirt, from spraying water during pump cleaning procedure.

Adjustable feet

The solution allows easy cleaning of the surface underneath the pump. It can also prove useful when there is a need to move the pump to a different location.

Casing drainage

The drain connection at the bottom of the pump casing allows to fully drain the pumped liquid from the casing.

Connection dimensions

| Model | DIN 11851 thread (std.) | DIN 32676 clamp | SMS3017 clamp | SMS 1145 thread | RJT thread | |||||

| Inlet | Outlet | Inlet | Outlet | Inlet | Outlet | Inlet | Outlet | Inlet | Outlet | |

| CTX 40-165 | DN40 | DN32 | DN40 | DN32 | 38 | 33.7 | 38 | 32 | 1.5” | 1.25” |

| CTX 50-145 | DN50 | DN40 | DN50 | DN40 | 51 | 38 | 51 | 38 | 2” | 1.5” |

| CTX 50-200 | DN50 | DN40 | DN50 | DN40 | 51 | 38 | 51 | 38 | 2” | 1.5” |

| CTX 65-175 | DN65 | DN50 | DN65 | DN50 | 63.5 | 51 | 63.5 | 51 | 2.5” | 2” |

| CTX 65-230 | DN65 | DN50 | DN65 | DN50 | 63.5 | 51 | 63.5 | 51 | 2.5” | 2” |

| CTX 65-240 | DN65 | DN40 | DN65 | DN40 | 63.5 | 38 | 63.5 | 38 | 2.5” | 1.5” |

| CTX 80-205 | DN80 | DN50 | DN80 | DN50 | 76.1 | 51 | 76 | 51 | 3” | 2” |

| CTX 80-212 | DN80 | DN65 | DN80 | DN65 | 76.1 | 63.5 | 76 | 63.5 | 3” | 2.5” |

| CTX 80-260 | DN80 | DN65 | DN80 | DN65 | 76.1 | 63.5 | 76 | 63.5 | 3” | 2.5” |

| CTX 100-230 | DN100 | DN80 | DN100 | DN80 | 101.6 | 76.1 | 101.6 | 76 | 4” | 3” |